Tutorial

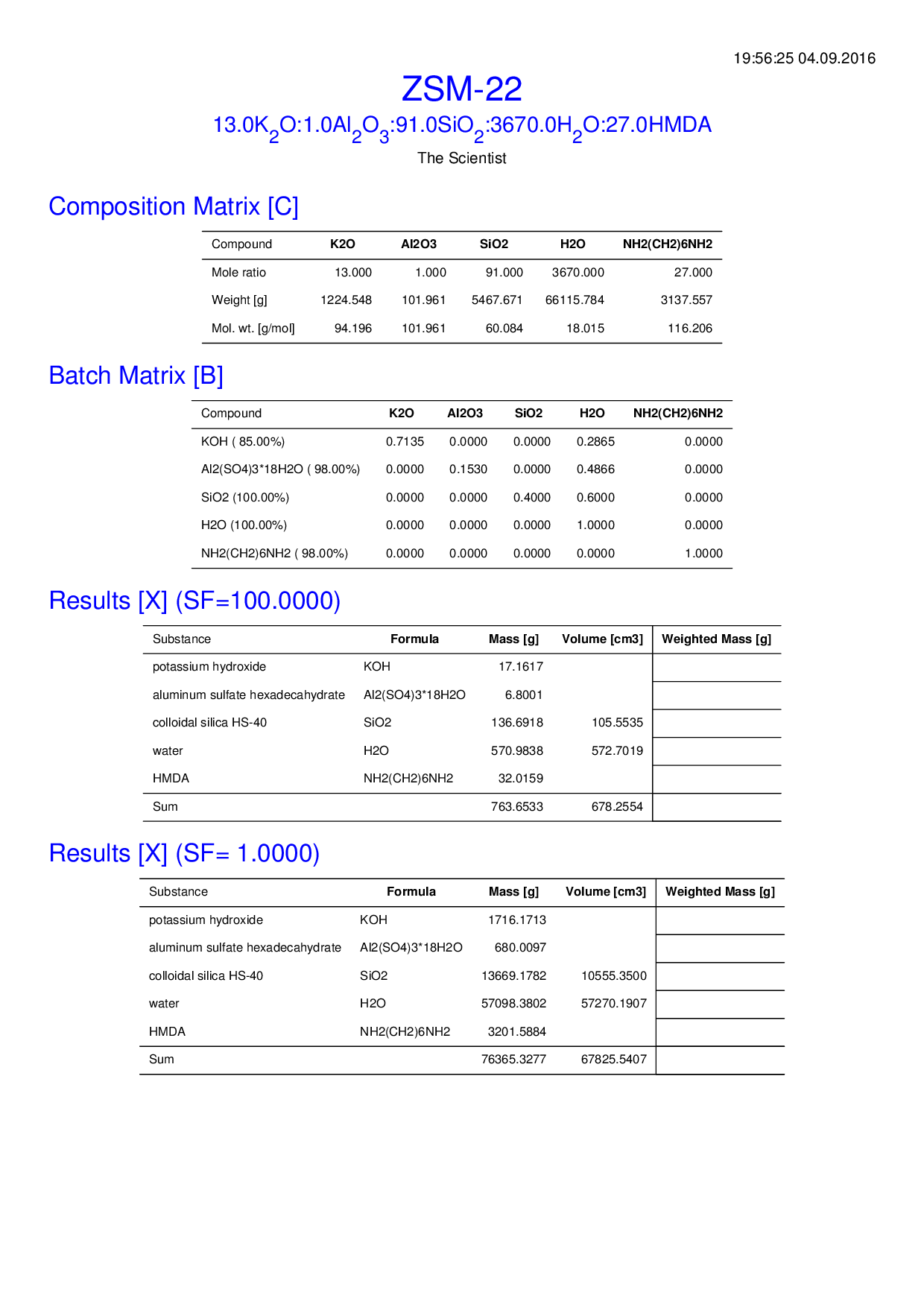

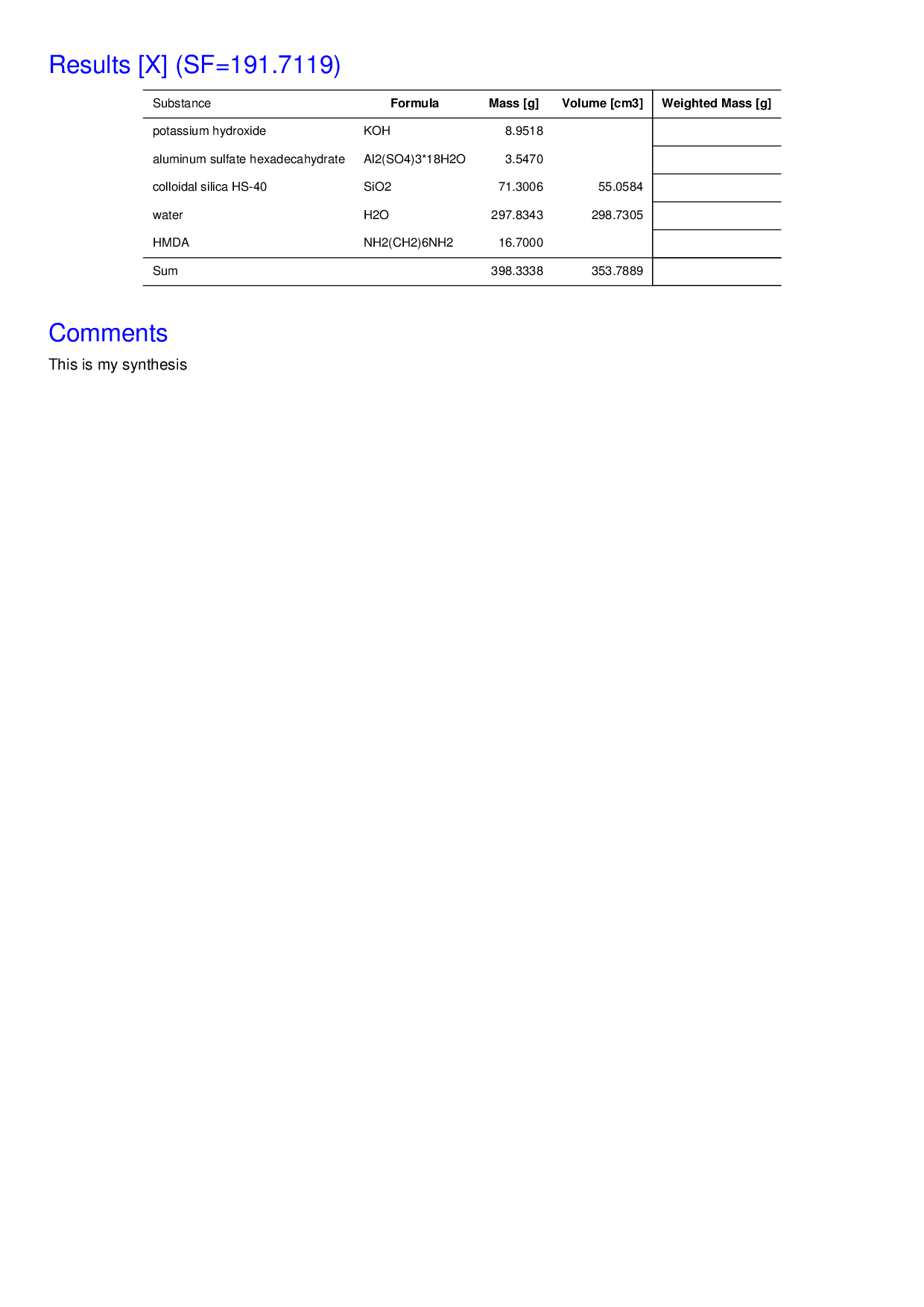

To illustrate the usage of the Batch Calculator we will calculate the the amounts of reactants required to perform the synthesis of ZSM-22 described by Ernst et al. [1].

The batch composition is given as (p. 139 of [1]):

- 13 K2O

- Al2O3

- 91 SiO2

- 3670 H20

- 27 NH2(CH2)6NH2

The reactants used are:

- silica sol (40% silica; Ludox AS40, DuPont)

- Al2(SO4)3* 18H2 O

- KOH

- 1,6-diaminohexane (HMDA)

- water

The amounts of reactants used in the synthesis are presented in the table below for reference

| Name | Amount [g] |

|---|---|

| KOH | 7.8 |

| Al2(SO4)3 | 3.5 |

| silica sol | 72 |

| water | 301 |

| HDMA | 16.7 |

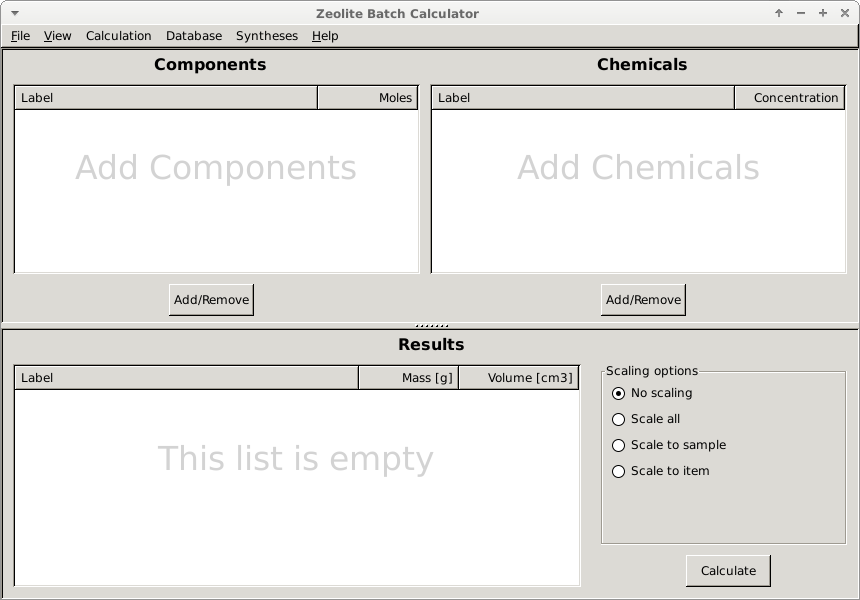

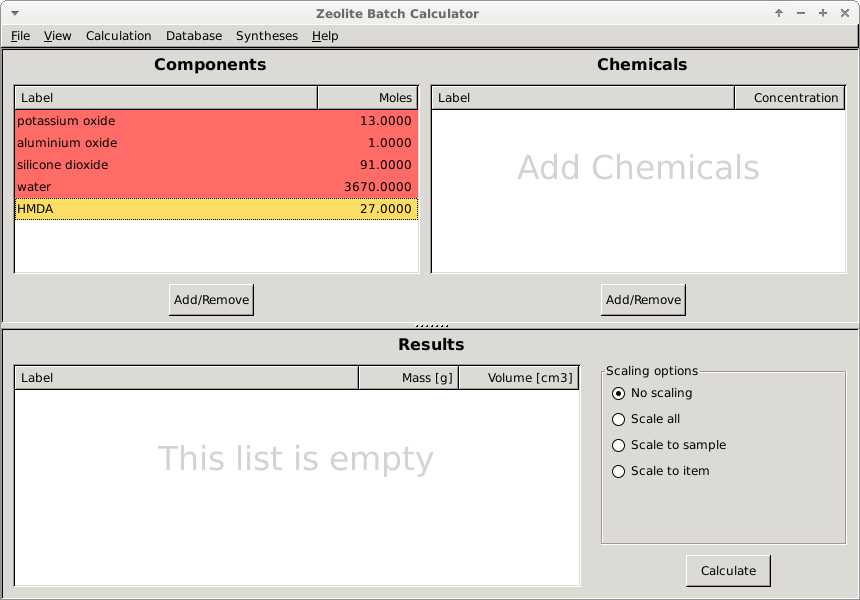

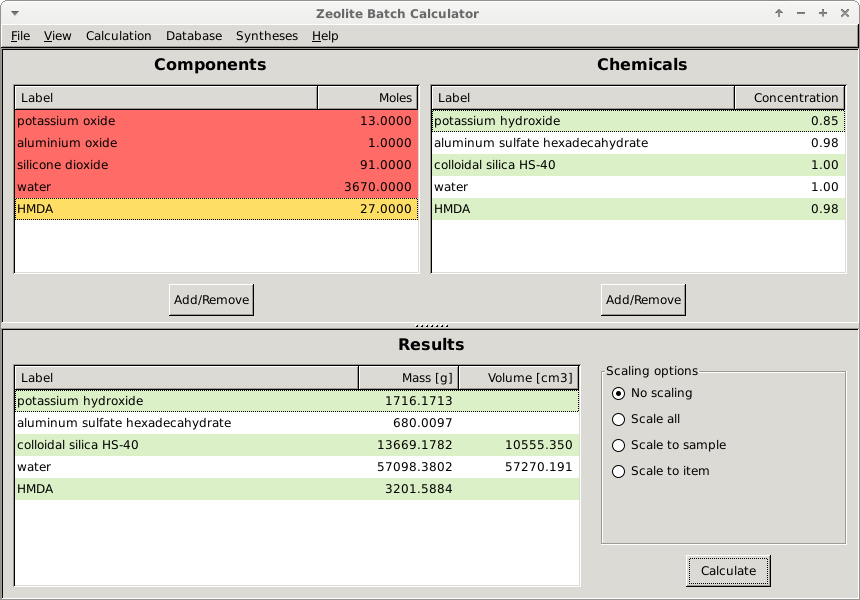

After starting the Batch Calculator the main window appears. As a first step we need to add the components by clicking on the Add/Remove button in the Components panel.

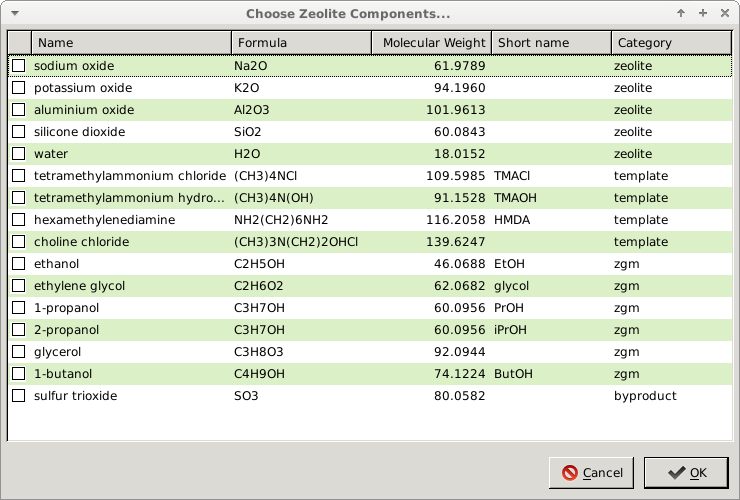

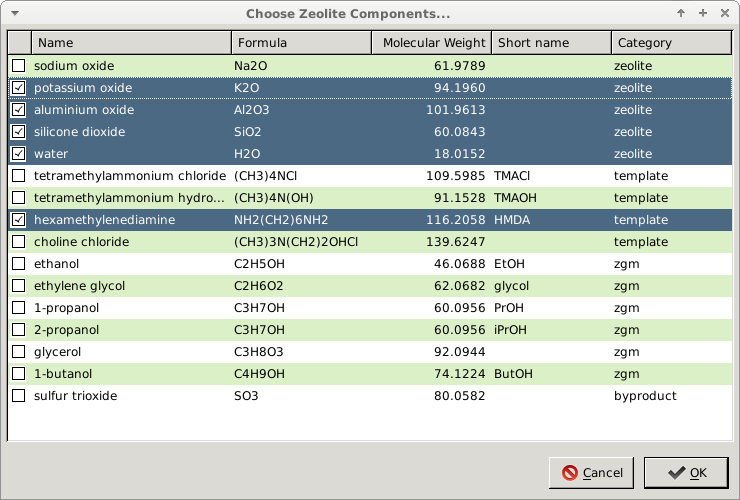

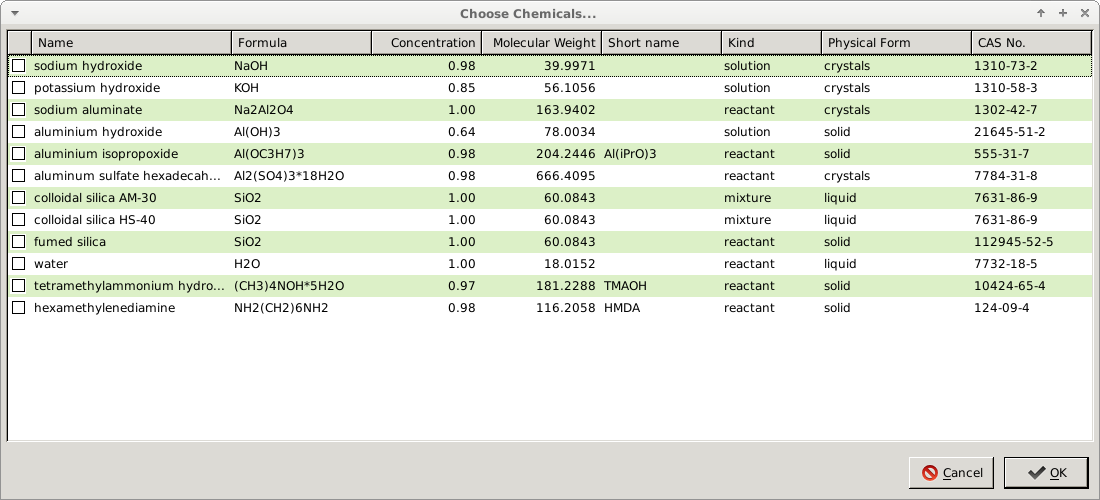

A dialog window should appear with all the components that are currently available in the database.

We need to choose the appropriate components by ticking the correct boxes as shown below and click the OK button.

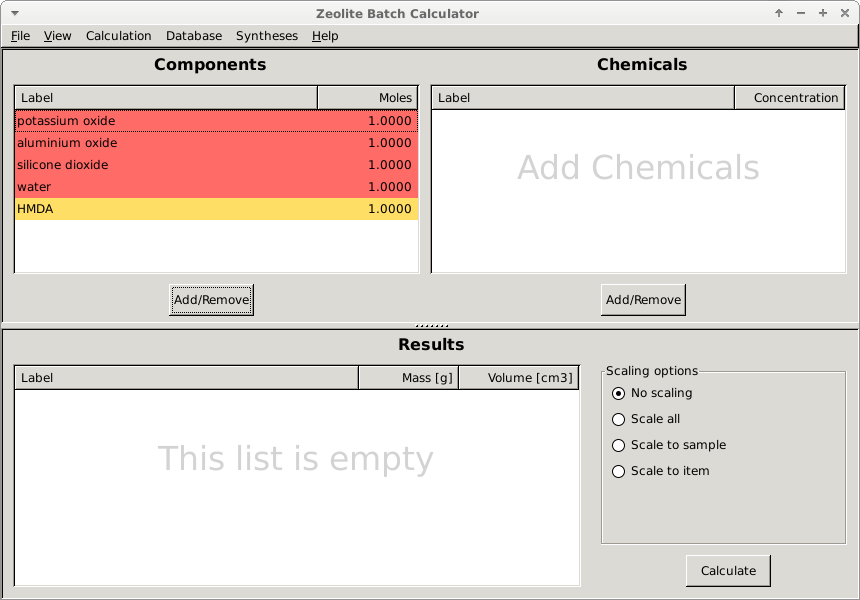

By doing that the selected components are now shown in the main window with the default amounts equal to 1.

To adjust the amount double click on the appropriate number and enter the correct amount, in our case the amounts are:

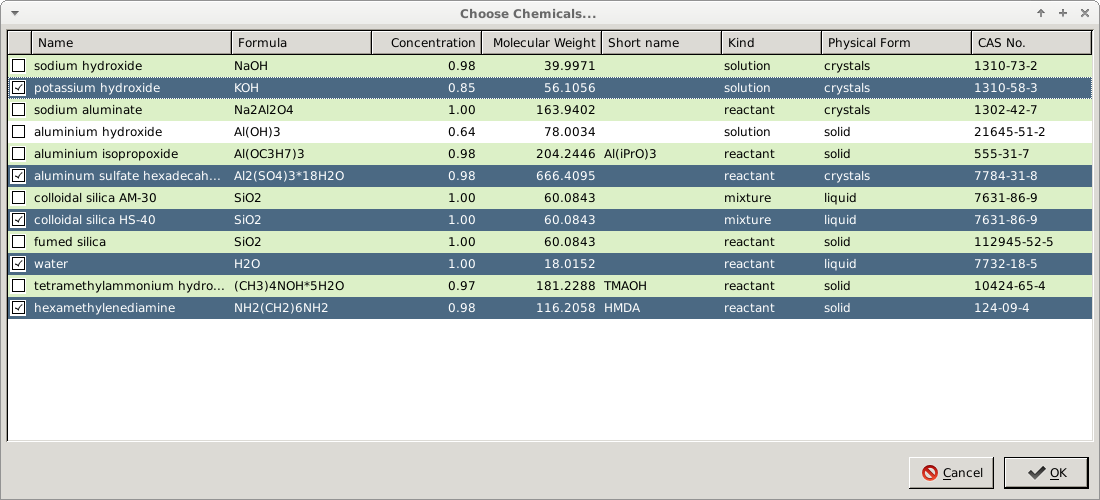

Now we need to add the chemicals by clicking the Add/Remove button in the Chemicals panel to open the dialog with all the chemicals in the database that are potential sources for the selected components

We can now select the appropriate chemicals by ticking the boxes in the first column and click OK.

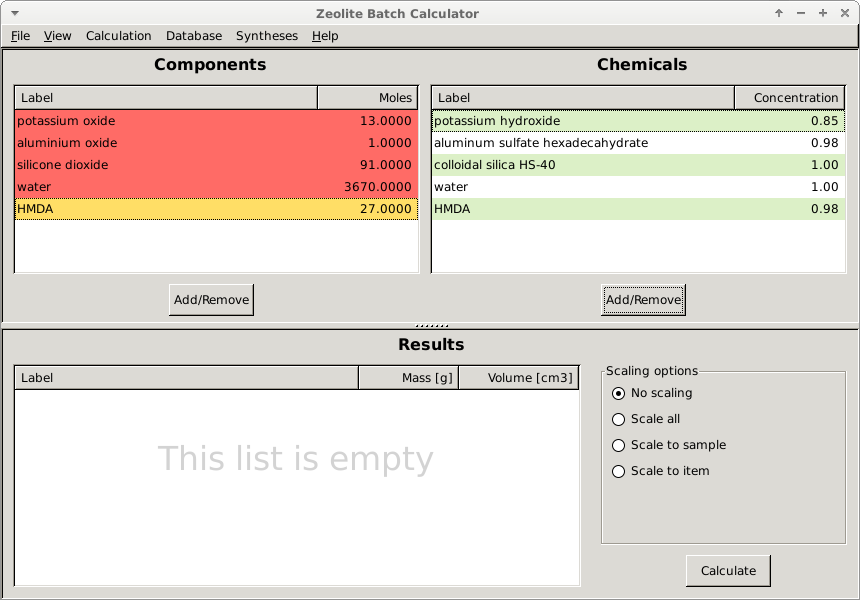

We can see that the chemical we successfully added to the main window with their default concentration/purities depending on the kind of chemical. The concentrations/purities can be adjusted in the same way as the amounts of components by double clicking the fields and entering the desired values.

By clicking the Calculate button, the calculation will be performed and the result will appear in the Results panel.

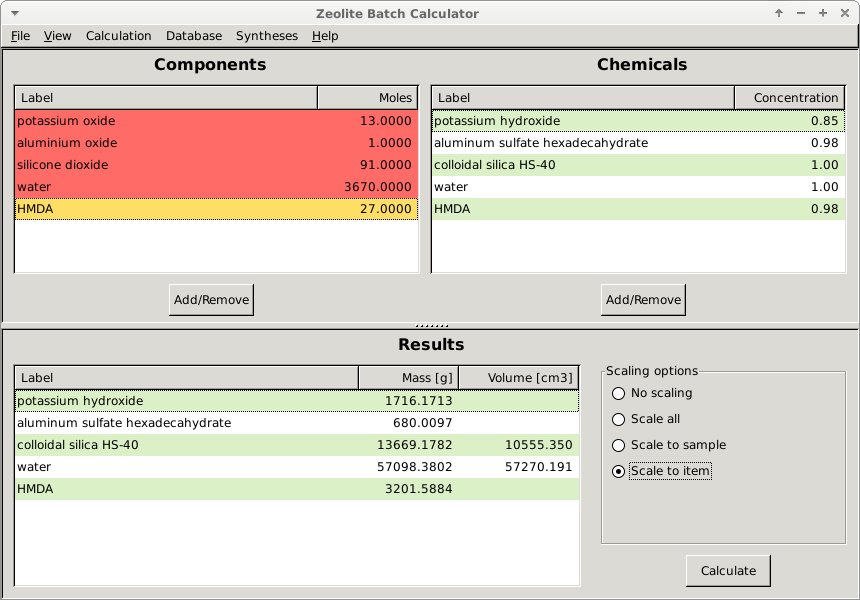

On the right hand side of the Results panel are the scaling options to adjust the batch size. In order to compare our results to the ones used in the paper we will rescale all the masses to the 16.7 g of HDMA using the Scale to item option.

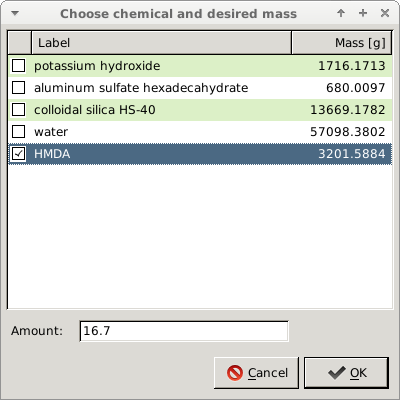

After selecting that option and clicking Calculate again a dialog will appear where we will select HMDA and enter a value of 16.7 to scale all the masses (and volumes) to 16.7 g of HMDA and click OK.

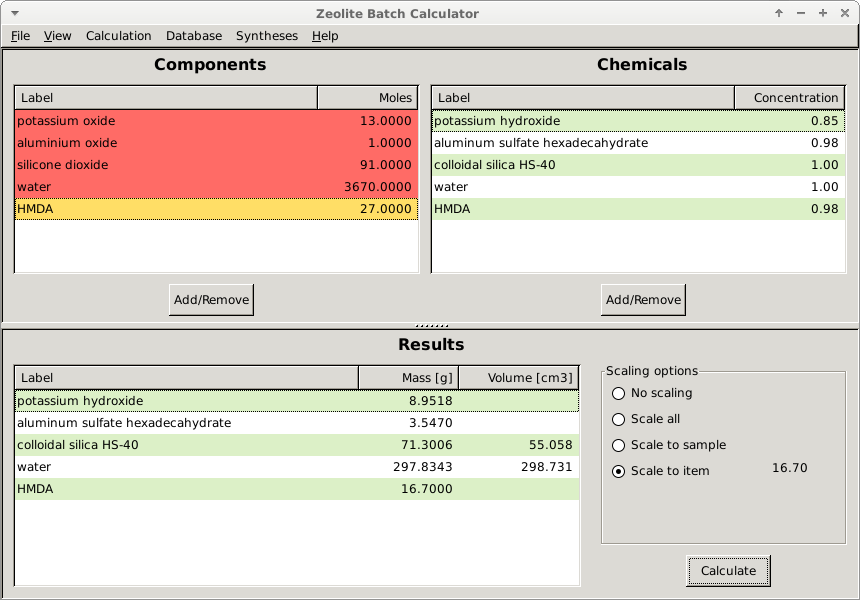

The updated masses are now shown in the Results panel instead of the initial results.

The result can be stored internally for further reference or modification by clicking the Add current option from the Syntheses drop down menu

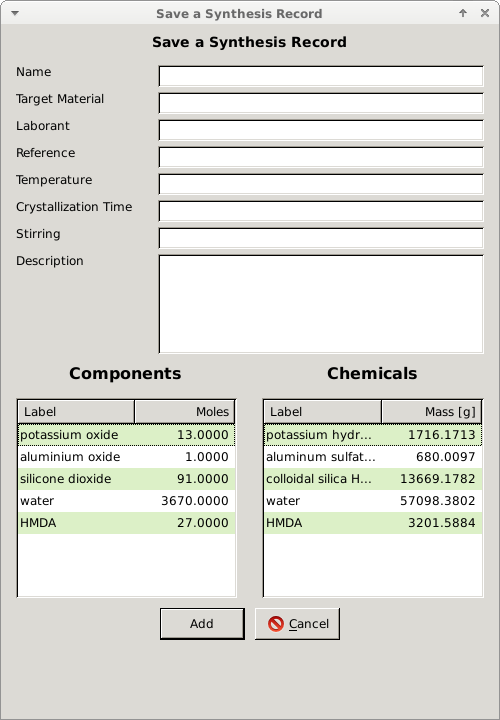

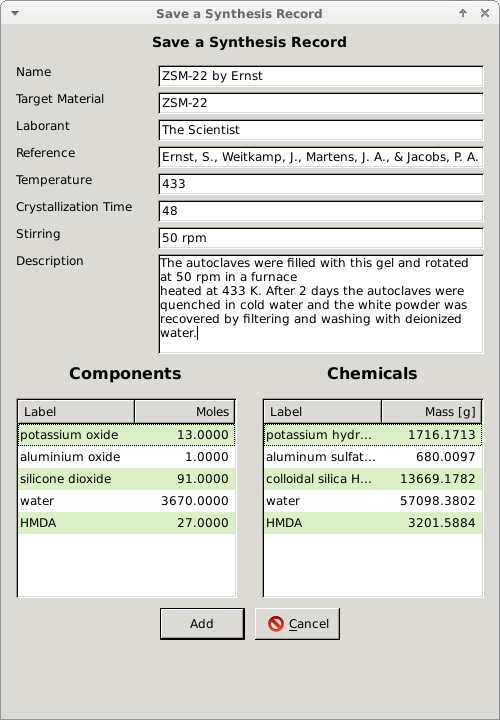

A dialog will be opened with an option to provide additional information about the synthesis of the material

After filling in the form we can click the Add button that will store the information in the internal database.

The dialog confirming the success of the modification should be displayed.

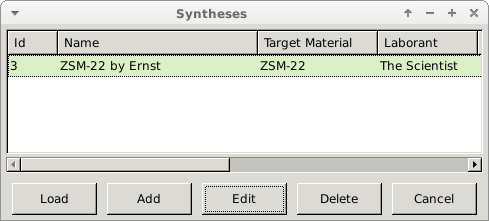

To verify or access the stored syntheses go to the Syntheses menu and select Show All which will open up a dialog with the stored records. From here the syntheses can be loaded back into the Batch Calculator deleted or modified.

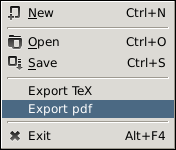

To finalize we can export a lab report for this synthesis by selecting the Export to pdf option from the File menu

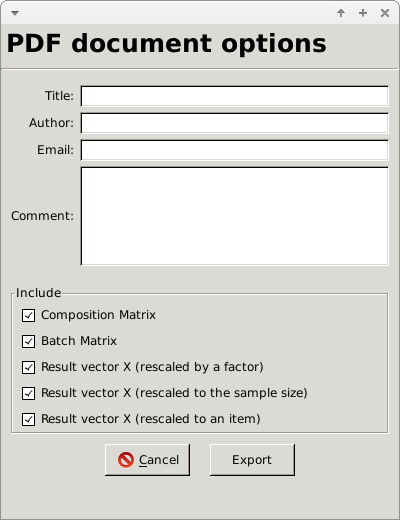

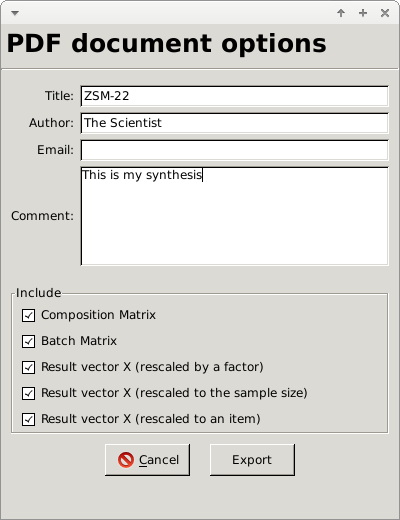

Another dialog appears with additional options for the report, where also the sections of the report can be chosen

After filling out the details and clicking Export

a dialog will appear to choose the file name and finally a message should appear that the pdf was successfully generated.

The report should like similar to the one below

| [1] | (1, 2) Ernst, S., Weitkamp, J., Martens, J. A., & Jacobs, P. A. (1989). Synthesis and shape-selective properties of ZSM-22. Applied Catalysis, 48(1), 137–148. doi:/10.1016/S0166-9834(00)80271-7 |